The Industrial Evolution of Turbocharger Diagram

In the ever-evolving industrial landscape, efficiency and performance are at the core of innovation. One such breakthrough that has revolutionized industrial machinery and heavy-duty engines is the turbocharger diagram. This essential component blueprint provides a clear structure for optimizing engine power, fuel efficiency, and emission control. As industries strive for higher productivity with minimal resource wastage, understanding and implementing an advanced turbocharger diagram becomes crucial.

What is a Turbocharger Diagram?

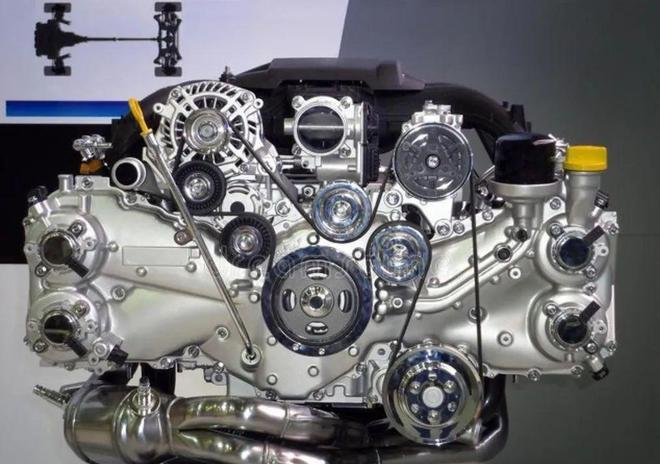

A turbocharger diagram is a structural and functional representation of a turbocharging system used in internal combustion engines. It illustrates key components such as the turbine, compressor, intercooler, and wastegate, along with their interactions to maximize engine efficiency. Industrial applications of turbocharger diagram technology are widespread, including in manufacturing plants, heavy-duty vehicles, power generation, and aerospace engineering.

The Advantages of a Turbocharger Diagram in Industrial Applications

Enhanced Power Output & Efficiency

One of the most significant advantages of the turbocharger diagram is its ability to increase engine power without requiring a larger engine size. By utilizing exhaust gases to drive the turbine, the turbocharger compresses the intake air, resulting in a more powerful combustion process. This leads to:

Higher torque output for heavy machinery

Optimized fuel consumptio

Reduced energy wastage

Superior Fuel Economy & Cost Reduction

Industries are constantly seeking ways to reduce operational costs, and an optimized turbocharger diagram plays a pivotal role in achieving this goal. By efficiently compressing air and improving the combustion process, fuel consumption is reduced while maintaining high levels of performance. This translates to:

Lower fuel expenses

Extended engine lifespan

Reduced maintenance costs

Eco-Friendly and Sustainable Operations

Environmental regulations are becoming stricter, and companies are looking for ways to meet compliance while maintaining operational efficiency. A well-structured turbocharger diagram significantly lowers emissions by ensuring optimal combustion. Benefits include:

Reduced carbon footprint

Compliance with environmental standards

Improved air quality in industrial zones

Increased Reliability and Durability

Industrial engines operate under extreme conditions, requiring components that can withstand high stress and temperature fluctuations. A well-designed turbocharger diagram ensures:

Longer operational lifespans

Minimal engine wear and tear

Enhanced durability in harsh environments

Future Trends in Turbocharger Diagram Development

Integration with Smart Sensors and AI

The future of the turbocharger diagram is deeply intertwined with digital transformation. Smart sensors and AI-driven diagnostics are being integrated to:

Monitor real-time performance

Predict maintenance needs

Optimize efficiency based on workload requirements

Advanced Materials and 3D Printing Applications

Innovations in materials science are reshaping turbocharger diagram designs. The use of lightweight, heat-resistant materials and 3D printing is leading to:

Reduced component weight

Enhanced heat dissipation

Increased efficiency with custom-engineered parts

Hybrid and Electrified Turbocharging Systems

As industries shift towards hybrid and electric solutions, turbocharger diagram technology is evolving to integrate electric-assisted turbocharging. This provides:

Instant boost at lower RPMs

Improved efficiency in hybrid powertrains

Reduced turbo lag for smoother performance

The Industrial Necessity of Turbocharger Diagram

The industrial world demands efficiency, reliability, and sustainability—qualities that a well-optimized turbocharger diagram delivers seamlessly. Whether in heavy machinery, power generation, or cutting-edge manufacturing processes, turbocharger technology is not just a performance enhancer but a necessity for the future. Companies that invest in state-of-the-art turbocharger diagram solutions will gain a competitive edge, ensuring maximum output with minimal resource consumption.

As industries move forward, embracing these advancements will pave the way for a more powerful, sustainable, and cost-effective future. The turbocharger diagram is not just an engine component—it’s a symbol of industrial innovation and progress.