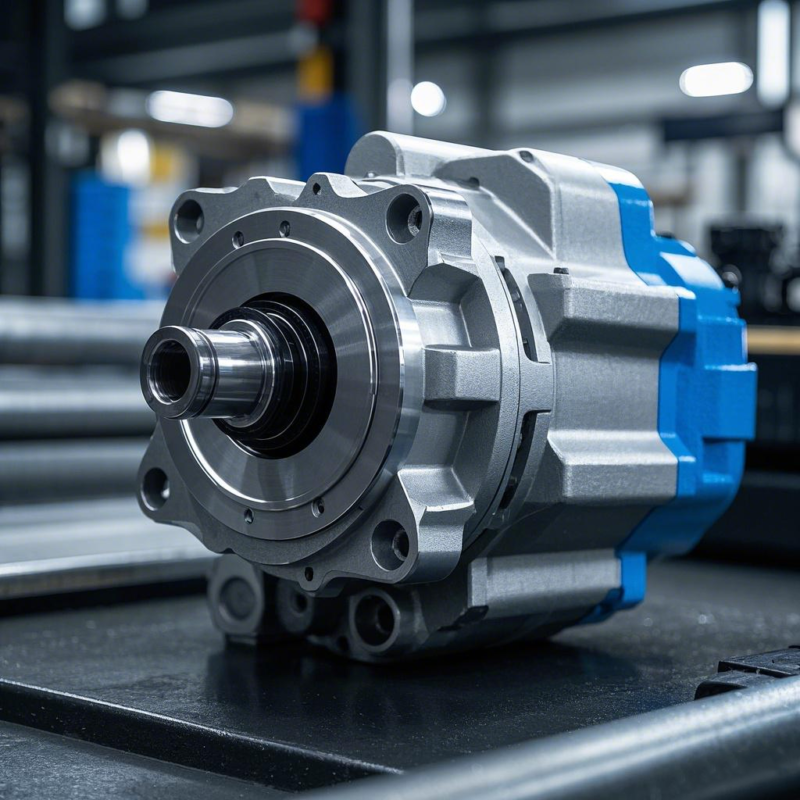

Hydraulic motors are an essential component in various industries, providing power and efficiency to machinery in applications ranging from construction equipment to manufacturing processes. By converting hydraulic energy into mechanical motion, hydraulic motors play a crucial role in many sectors. In this guide, we will explore the different types of hydraulic motors, how they work, their benefits, and common applications, as well as tips for maintenance and selection.

What is a Hydraulic Motor?

A hydraulic motor is a mechanical device that converts hydraulic energy, provided by a hydraulic pump, into rotational mechanical energy. The motor works by using pressurized hydraulic fluid to generate torque, which powers various systems or machinery. The high power density and ability to deliver constant torque make hydraulic motors indispensable in applications requiring smooth, reliable, and efficient motion.

In simple terms, a hydraulic motor operates on the principle of fluid power, using pressurized fluid to drive a motor that produces rotational energy. The torque generated by the motor depends on the pressure of the fluid and the design of the motor itself.

Key Features of Hydraulic Motors:

- High power density: Can generate high torque in a compact form factor.

- Precise control: Allows for variable speed and direction control, offering flexibility in a range of applications.

- Durability: Designed to handle tough, demanding environments while operating under high pressure and temperature.

- Efficiency: Capable of producing a lot of power with relatively low input, especially in heavy-duty applications.

Types of Hydraulic Motors

There are several types of hydraulic motors, each with unique characteristics suited for specific applications. These motors are generally classified into two categories: gear motors and piston motors. Below, we’ll dive into each of these categories and their subtypes.

1. Gear Motors

Gear motors are the simplest and most common type of hydraulic motors. They use gears to convert hydraulic fluid pressure into rotational motion. Gear motors are known for their simplicity, compactness, and cost-effectiveness.

- External Gear Motors: These motors use two gears, one of which is driven by the hydraulic fluid, while the other gear turns as a result of the mechanical contact. External gear motors are widely used in industrial applications where cost-effectiveness is crucial, such as in mobile machinery and small devices.

- Internal Gear Motors: Internal gear motors feature one gear that rotates inside another. This type of motor can handle higher torque and operate with smoother motion than external gear motors, making them suitable for more demanding tasks.

Advantages of Gear Motors:

- Simple and cost-effective design.

- Reliable for applications requiring consistent speed and moderate torque.

- Easy to maintain due to their straightforward construction.

2. Vane Motors

Vane motors use a rotor with multiple vanes to create a sealed chamber where hydraulic fluid pressure is converted into torque. These motors are known for providing smooth operation, even under varying loads.

Applications of Vane Motors:

- Small equipment such as pumps, fans, and conveyors.

- Ideal for low to medium power applications where smooth operation is essential.

Advantages of Vane Motors:

- Smooth and quiet operation.

- Provide high torque at low speeds.

- Compact design and efficient in small and medium applications.

3. Piston Motors

Piston motors are a more complex and high-performance type of hydraulic motor. They use multiple pistons to convert hydraulic fluid energy into mechanical power. These motors can generate high torque and operate efficiently under varying conditions.

- Axial Piston Motors: In these motors, the pistons are arranged along a central axis and move in and out in response to hydraulic pressure. Axial piston motors are known for their ability to provide high efficiency and torque density.

- Radial Piston Motors: These motors feature pistons arranged radially around a central drive shaft. Radial piston motors are ideal for applications requiring high starting torque and low speeds.

Applications of Piston Motors:

- Heavy-duty equipment such as construction vehicles and mining machinery.

- Applications requiring high torque, such as winches, hoists, and rollers.

Advantages of Piston Motors:

- High efficiency and power density.

- Capable of providing high torque even at low speeds.

- Versatile and suited for high-performance applications.

How Do Hydraulic Motors Work?

The core functionality of a hydraulic motor lies in its ability to convert hydraulic energy into mechanical motion. Below is a simplified explanation of how hydraulic motors work:

- Pressurized Fluid: A hydraulic pump pressurizes hydraulic fluid, which is then directed into the motor.

- Fluid Movement: As the pressurized fluid enters the motor, it pushes against the internal components (such as gears, pistons, or vanes), causing them to move.

- Torque Generation: This movement causes the motor shaft to rotate, creating mechanical power in the form of torque. The rotational motion generated can then be used to power machinery or other systems.

- Return of Fluid: After passing through the motor, the hydraulic fluid exits the motor and returns to the hydraulic reservoir, where it is filtered and ready for reuse.

Benefits of Using Hydraulic Motors

Hydraulic motors offer several advantages over other types of motors, making them the preferred choice in many industrial and mobile applications. Here are some of the key benefits of hydraulic motors:

1. High Torque in Compact Size

Hydraulic motors are known for their ability to deliver high torque in a relatively small and compact package. This makes them ideal for applications where space is limited, but high power is still needed, such as in construction equipment, vehicles, and mobile machinery.

2. Precise Control

Hydraulic motors allow for excellent speed control and can be easily adjusted to provide variable speeds and precise torque. This makes them perfect for applications that require fine-tuned control, such as in robotics, manufacturing processes, and winching systems.

3. Efficiency and Power Density

One of the standout features of hydraulic motors is their high power density. They can deliver substantial power with relatively low input, which makes them highly efficient, especially in applications requiring significant force. This is particularly useful in industries like mining, construction, and manufacturing, where power-to-size ratio is critical.

4. Reliability and Durability

Hydraulic motors are incredibly durable and can operate in demanding environments. They can withstand high pressures, extreme temperatures, and harsh conditions, making them reliable in heavy-duty machinery and industrial applications.

Applications of Hydraulic Motors

Hydraulic motors are used in a wide variety of applications due to their efficiency, reliability, and versatility. Below are some of the most common industries and applications where hydraulic motors are used:

1. Construction and Heavy Machinery

Construction equipment such as excavators, bulldozers, and backhoes rely on hydraulic motors to provide high torque and control in demanding environments. Hydraulic motors are used to power the drive systems of these machines, as well as functions like steering, lifting, and digging.

2. Agriculture and Forestry

In agricultural and forestry machinery, hydraulic motors are used to power various implements, such as harvesters, plows, and irrigation systems. They provide the necessary torque to drive equipment that operates under heavy loads and varying terrain.

3. Mining and Material Handling

Mining operations and material handling systems often use hydraulic motors to drive conveyors, winches, crushers, and other heavy-duty machinery. These motors help transport materials efficiently and operate in rugged environments where reliability is key.

4. Marine Applications

Hydraulic motors are used in marine applications to power systems such as winches, steering systems, and lifting equipment. Their ability to operate under high-pressure conditions makes them ideal for harsh marine environments.

5. Automotive and Mobile Equipment

Hydraulic motors are often used in mobile equipment like trucks, buses, and specialized vehicles. They can be used for tasks such as power steering, hoisting, and drive systems, providing the necessary power for efficient operation.

Maintenance and Troubleshooting of Hydraulic Motors

Proper maintenance of hydraulic motors is critical to ensuring their longevity and performance. Below are some tips for maintaining and troubleshooting hydraulic motors:

1. Regular Fluid Checks

Check the hydraulic fluid level regularly to ensure it is at the proper level. Low fluid levels can cause the motor to operate inefficiently or lead to premature wear.

2. Inspect for Leaks

Hydraulic systems are under high pressure, and even small leaks can reduce efficiency and cause damage. Regularly inspect hoses, fittings, and the motor itself for any signs of leaks.

3. Replace Filters

The hydraulic fluid passes through filters that help keep the system clean. Over time, these filters can become clogged with debris, so it’s important to replace them regularly to maintain optimal motor performance.

4. Monitor Temperature

Hydraulic motors can become overheated, especially under heavy loads. It’s important to monitor the temperature and ensure the motor operates within its recommended temperature range to avoid damage.

Harnessing the Power of Hydraulic Motors

Hydraulic motors are incredibly versatile and powerful components that are used across a variety of industries. From construction machinery to automotive systems, these motors provide efficient power and reliable performance. By understanding the different types of hydraulic motors, how they work, and their benefits, you can make informed decisions when selecting the right motor for your application. Regular maintenance and proper care will ensure that your hydraulic motor delivers optimal performance, helping you maximize productivity and reduce downtime.